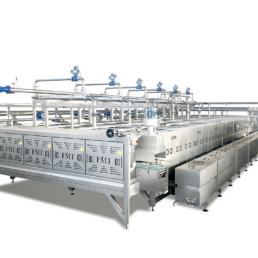

Monoblock

SPEED from 150 to 800 CPM

(*) The speed depends on the valve configuration, on the container and the product to be filled

Filling systems for glass or plastic containers. Processed products: liquid, dense, semi-dense; all these products may or may not have: pieces, pulps or fibres. The range of products includes, among others: tomato purée, jams, mayonnaise, ketchup, sauces, pâté, edible oils, creams, baby food, honey, yoghurt, etc.

Operator interface with touch screen panel and simple and intuitive service menu;

Specifications

- High degree of accuracy and cleanliness thanks to the possibility of closing the Monoblock with roofing;

- Maximum optimisation of the plant spaces having only one machine for washing, filling and closing the containers.

- Customisation in the washing treatment on empty container

- Quick format change.

Accessories

- Neck handling when possible;

- Internal overpressure with air treatment with HEPA filters;

- Bottom filling device;

- Temperature recording system of the product in the hopper.

- Three-way inlet valve with temperature control.

- Possibility of using the Piston Filler with membrane valves or valves with plunger

Contact Us

Request pricing or any additional information