Depalletisers

FMT has developed its range of automatic depalletisers with particular attention to flexibility, in order to be able to process different types of containers with the same machine.

Thanks to the development by “blocks”, each Customer can personalize the machine in relation to the degree of required automation.

In fact, the FMT Depalletisers can be composed starting from a semi-automatic machine up to a “full optional” model, with a maximum degree of automation and autonomy even at high line speeds (up to 1.000 cpm)

Special attention to the choice of high quality materials and a sturdy structure are the key elements of this FMT product range, that make it possible for us to ensure high performance levels over the years.

The different Depalletiser models can be equipped with:

- Automatic system for the withdrawal of layer pads

- Automatic pallet feeding and unloading system

- Buffer belt conveyor and alignment system, on a single row, for containers outfeed

- Low level - GEMINI Model.

- High level - ATHENA Model

Traditional Palletisers

FMT has developed its range of automatic palletisers for processing cartons, shrink-wrapped packs and trays.

The product can be fed from above or below

The palletiser can also be of the Multiliner type, capable of processing simultaneously two or more types of differently sized packages and capable of palletising them separately

Special attention to the choice of high quality materials and a sturdy structure are the key elements of this FMT product range that make it possible for us to ensure high performance levels over the years.

The different palletiser models can be equipped with:

- Automatic layer pad deposit system

- Pallet destacker storage unit

- Integration with automatic pallet winder

The palletisers can have two configurations

Storage Systems / Conveyors

As a supplier of complete lines, over the years FMT has developed several containers handling systems to meet the needs of its Customers.

In fact, in order to have lines with high production efficiency, it is essential to have conveyors and storage systems with high quality and advanced technology.

Behind each line, there is a very important engineering design that uses all available handling technologies to be able to develop the best final solution for each project.

Among the various FMT systems to complete its lines, we have:

- Belt conveyors

- Elevators / lowering devices for cartons or single containers

- Drying tunnel

- Empty or full containers washing machines

- Buffer (FIFO or LIFO)

- Containers overturning machines

- Tilting conveyors for cap sterilisation (Hot Fill)

Robot Palletisers

The ZEUS Robotic palletising systems are developed to meet the most modern needs of the food industry. Thanks to a wide variety of special multifunction heads, they are able to meet the packaging needs of most containers and packages.

In particular, they represent an alternative to traditional palletising systems.

The possible coupling with suction cup pick-up systems and arms on the heads enables the combined pick-up of empty layer pads and pallets.

The ZEUS Robotic palletising has been developed for both low speed and high speed.

SPEED from 3 to 120 ppm

(*) The speed depends on the size of the package and the palletising layout.

The Palletising system with Robot has different customisation options. Its main feature is flexibility, as it is a technology that can be configured based on the specific customer requests:

- Possibility of palletising several lines simultaneously

- Ability to palletise packages of different size and type simultaneously

- In most cases, format change without the need for mechanical intervention. Carried out by program insertion or selection

- Limited installation space

- Expandable for increased production

- Reliability, flexibility and possibility to reconvert the system

- High residual value of the robot over time

- Pick-up head with suction cups

- Pick-up head with pneumatic or motorised grippers

- Pick-up head with rack

- Magnetic pick-up head

- Basket pick-up head

- etc....

Palletizer configurations:

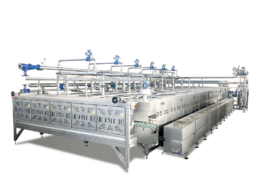

Horizontal Tunnels

HORIZONTAL TUNNEL FOR PRODUCT THERMAL TREATMENT

It is a modular range of Tunnels for pasteurising, warming and cooling food products inside different types of container: cans, glass bottles and jars, plastic bottles.

The modular belt conveyor system ensures a

significant product stability, making operation extremely simple and reducing significantly maintenance.

The product can be handled on one or two stacked levels.

The simple operation and maintenance as well as the quality of the treatment performed, make the FMT Tunnels ideal machines for the pasteurising, warming and cooling cycles of all types of contain

An extremely flexible and innovative work platform, designed to meet the pasteurisation needs of the most demanding Customers.

Advanced technological solutions that enable FMT to manufacture machines at the highest levels available on the market today.

- Fast and accurate thermal treatment

- Maximum care for the most delicate products

- Modular configuration

- Energy saving systems

- Pasteurisation Tunnel

- Calorie recovery Pasteurisation Tunnel

- Heating Tunnel

- Cooling Tunnel

The various technologies of horizontal tunnels can be found in four machine versions:

Filler with flow meter

This technology is ideal for filling fruit and vegetable juices, fresh or microfiltered milk, drinking yoghurt, liqueurs and spirits, mineral water and wine into glass and plastic containers or cans.

By using an electronic technology for the filling phase, the Filler with flow meters has the advantage of being a very hygienic and easy to clean equipment.

The volumetric filling technology with Flow meters has been developed for both low and high speeds, always starting from a hygienic, reliable and high quality design, specifically designed for the beverage market

The Filler has different customisation options in relation to the type of product to be filled or the container to be processed, such as:

- Filling valve with magnetic or mass flow meter

- Automatic filling volume adjustment

- Flush bottle mouth filling, without contact

- Parts in contact with the product in AISI 304 stainless steel (AISI 316 on request)

- Quick format change equipment with the option of neck handling for both PET bottles and glass bottles

- Filling valve with electro-pneumatic control to eliminate product leakage at the end of filling.

- External product feeding tank set-up to work in overpressure, or possibility of flushing with inert gas.

- Automatic dummy bottles connection/disconnection for the CIP phase.

- On request, it is possible to provide a special “dynamic pressurisation” configuration with the machine completely closed and with filtered air injected into it, to avoid product contamination

Isobaric Filler

This technology is ideal for filling carbonated drinks, sparkling water, beer and wine into glass and plastic containers or cans.

The isobaric filling technology has been developed for both low and high speeds, always starting from a hygienic, reliable and high quality design, specifically designed for the beverage market

The Filler has different customisation options in relation to the type of product to be filled or the container to be processed:

- Filling valve with magnetic flow meter

- Automatic filling volume adjustment

- Contact filling valve

- Parts in contact with the product in AISI 304 stainless steel (AISI 316 on request)

- Quick format change equipment with the option of neck handling in case of PET bottles

- Product tank with slip ring

- Separate air pressurisation and air return carried out through membrane valve

- Pneumatic control of the various filling phases

- Automatic dummy bottles connection/disconnection for the CIP phase.

- On request, it is possible to provide a special “dynamic pressurisation” configuration with the machine completely closed and with filtered air injected into it, to avoid product contamination

The isobaric filler technology can be supplied in the following versions

Closing Systems

Designed according to the highest quality standards, the FMT Seamers are suitable for closing various types of boxes, in tinplate, aluminium and plastic.

The consolidated reliability, flexibility and high hygiene values achieved, make these machines particularly suitable for various applications in the Food and Beverage sectors.

Available in stand-alone version or synchronised with Filler-Vacuum Filler, the FMT Seamers can be used for a production capacity of 40 up to 1.000 pieces/minute.

The FMT Seamers are characterised by:

- Control with Siemens PLC

- Sanitary design

- Centralised lubrication

- Height-adjustable heads

- Motorised plates

Based on the different needs in terms of production capacity, configuration and product to be processed, different options can be supplied on the FMT Seamers:

- Steam / CO2/ nitrogen injection

- Pre-arrangement for CIP

- Lids feeder with different lengths, with or without vibrator

- Special plates for boxes containing meat or fish

- Lid marker

- In motion timer

Hot Fill Filler

This technology is ideal for filling non-carbonated products such as RTD, fruit and vegetable juices, isotonic beverages, energy drinks, sport drinks and Ice Tea in glass and plastic containers or in cans

Hot filling is the most suitable solution for filling products without the risk of contamination and with a low investment.

The FMT Hot Fill Filler can have different types of valves to fit the needs of the product and of the container:

- Self-levelling valves (for bottles with long necks).

- Valves with a slight vacuum (glass only).

- Hybrid valves for HOT FILL and ISOBARIC filling

The HOT FILL technology has been developed for both low and high speeds, always starting from a hygienic, reliable and high quality design.

This technology has been specially developed for filling the product at high temperatures.

To ensure this, the machine is equipped with constant recirculation of the product in the valve and a filling temperature control.

- Parts in contact with the product in AISI 304 stainless steel (AISI 316 on request)

- Quick format change equipment with the option of neck handling in case of plastic bottles

- Filling and recirculation valves with electro-pneumatic control

- Product recirculation in valve to start filling only if the product temperature is correct

- Mobile filling valve to eliminate product leakage at the end of filling.

- On request, it is possible to provide a special “dynamic pressurisation” configuration, with the machine completely closed and with filtered air injected into it, to avoid product contamination