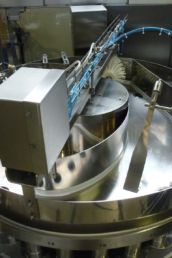

Capping machine

The FMT capping machines, entirely manufactured in stainless steel, are designed to permit the closing with or without steam of glass bottles and jars, through different types of caps.

The consolidated reliability, the easy format change and the high levels of vacuum and hygiene achieved, make these machines particularly suitable for the canned food and beverage sectors.

Thanks to the flexibility and modularity of their range, FMT Capping machines can be used both in low speed and high speed lines (up to 800 cpm).

Based on the different needs, in terms of production capacity and autonomy, different feeding models can be supplied with the machines.

CAPS FEEDERS

The FMT feeders allow the automatic and uniform feeding of caps, from the loading hopper to the capping machine, orienting them correctly.

Depending on the speeds and on the required autonomy, various models make up the range of FMT caps feeders, with a production range reaching up to 900 cpm.

Since the FMT feeders can be installed in a close or remote position with respect to the Capping machines, they are proposed and designed according to the available spaces and to the specifications of each project.

The Twist Off Capping machines can be found in four versions:

Depalletisers

FMT has developed its range of automatic depalletisers with particular attention to flexibility, in order to be able to process different types of containers with the same machine.

Thanks to the development by “blocks”, each Customer can personalize the machine in relation to the degree of required automation.

In fact, the FMT Depalletisers can be composed starting from a semi-automatic machine up to a “full optional” model, with a maximum degree of automation and autonomy even at high line speeds (up to 1.000 cpm)

Special attention to the choice of high quality materials and a sturdy structure are the key elements of this FMT product range, that make it possible for us to ensure high performance levels over the years.

The different Depalletiser models can be equipped with:

- Automatic system for the withdrawal of layer pads

- Automatic pallet feeding and unloading system

- Buffer belt conveyor and alignment system, on a single row, for containers outfeed

- Low level - GEMINI Model.

- High level - ATHENA Model

Traditional Palletisers

FMT has developed its range of automatic palletisers for processing cartons, shrink-wrapped packs and trays.

The product can be fed from above or below

The palletiser can also be of the Multiliner type, capable of processing simultaneously two or more types of differently sized packages and capable of palletising them separately

Special attention to the choice of high quality materials and a sturdy structure are the key elements of this FMT product range that make it possible for us to ensure high performance levels over the years.

The different palletiser models can be equipped with:

- Automatic layer pad deposit system

- Pallet destacker storage unit

- Integration with automatic pallet winder

The palletisers can have two configurations

Storage Systems / Conveyors

As a supplier of complete lines, over the years FMT has developed several containers handling systems to meet the needs of its Customers.

In fact, in order to have lines with high production efficiency, it is essential to have conveyors and storage systems with high quality and advanced technology.

Behind each line, there is a very important engineering design that uses all available handling technologies to be able to develop the best final solution for each project.

Among the various FMT systems to complete its lines, we have:

- Belt conveyors

- Elevators / lowering devices for cartons or single containers

- Drying tunnel

- Empty or full containers washing machines

- Buffer (FIFO or LIFO)

- Containers overturning machines

- Tilting conveyors for cap sterilisation (Hot Fill)

Palletiser / Depalletiser

Robotic palletising and depalletising system for unpacked containers.

The system is designed and studied to receive containers from the filling line, place them on pallets which will then be placed in quarantine or in storage units to be labelled at a later date

Subsequently, the pallets return to the Robot, which will depalletise the containers and send them to the secondary packaging line.

The system is tailor-made and gives the possibility of making maximum use of space available.

The possible coupling with suction cup pick-up systems and arms on the heads enables the combined pick-up of empty layer pads and empty pallets.

The technology of palletising and depalletising with robot was developed for both medium and high speeds.

The palletising and depalletising system with Robot has different customisation options. Its main feature is flexibility, as it is a technology that can be configured based on specific Customer’s requests:

- Possibility of managing both the palletising and depalletising functions with a single Robot.

- Various types of heads to be chosen according to the type of container, such as: metal cans, glass bottles and jars

- Very fast format change

- Expandable for increased production

- High residual value of the robot over time

- Reduced maintenance costs

Robot Palletisers

The ZEUS Robotic palletising systems are developed to meet the most modern needs of the food industry. Thanks to a wide variety of special multifunction heads, they are able to meet the packaging needs of most containers and packages.

In particular, they represent an alternative to traditional palletising systems.

The possible coupling with suction cup pick-up systems and arms on the heads enables the combined pick-up of empty layer pads and pallets.

The ZEUS Robotic palletising has been developed for both low speed and high speed.

SPEED from 3 to 120 ppm

(*) The speed depends on the size of the package and the palletising layout.

The Palletising system with Robot has different customisation options. Its main feature is flexibility, as it is a technology that can be configured based on the specific customer requests:

- Possibility of palletising several lines simultaneously

- Ability to palletise packages of different size and type simultaneously

- In most cases, format change without the need for mechanical intervention. Carried out by program insertion or selection

- Limited installation space

- Expandable for increased production

- Reliability, flexibility and possibility to reconvert the system

- High residual value of the robot over time

- Pick-up head with suction cups

- Pick-up head with pneumatic or motorised grippers

- Pick-up head with rack

- Magnetic pick-up head

- Basket pick-up head

- etc....

Palletizer configurations:

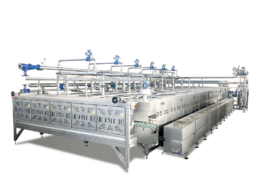

Horizontal Tunnels

HORIZONTAL TUNNEL FOR PRODUCT THERMAL TREATMENT

It is a modular range of Tunnels for pasteurising, warming and cooling food products inside different types of container: cans, glass bottles and jars, plastic bottles.

The modular belt conveyor system ensures a

significant product stability, making operation extremely simple and reducing significantly maintenance.

The product can be handled on one or two stacked levels.

The simple operation and maintenance as well as the quality of the treatment performed, make the FMT Tunnels ideal machines for the pasteurising, warming and cooling cycles of all types of contain

An extremely flexible and innovative work platform, designed to meet the pasteurisation needs of the most demanding Customers.

Advanced technological solutions that enable FMT to manufacture machines at the highest levels available on the market today.

- Fast and accurate thermal treatment

- Maximum care for the most delicate products

- Modular configuration

- Energy saving systems

- Pasteurisation Tunnel

- Calorie recovery Pasteurisation Tunnel

- Heating Tunnel

- Cooling Tunnel

The various technologies of horizontal tunnels can be found in four machine versions:

Telescopic Filler

This technology is ideal for filling solid, diced, sliced and granular products inside glass or plastic containers and in cans.

This type of machine is generally used for filling legumes, mushrooms, corn and fruit salads.

Main characteristic of the FMT Telescopic Fillers is the flexibility: with the same machine it is possible to fill different types of products.

Different types of configurations are available in FMT range, in order to offer solutions for both for low and high speed.

The Telescopic Filler has different customisation options in relation to the type of product to be filled or the container to be processed:

- Possibility of combining with Vacuum Fillers, for dosing the preserving liquid

- Special system to facilitate dosing of irregular products, difficult to process

Weight Filler

This technology is ideal for filling granular products, in pieces, and in general for all those applications where the weight inside the container must be guaranteed.

For example, weight filling is used for soluble preparations, spices, chopped fruit and vegetables.

The main characteristic of this type of machines is their accuracy, as they are able to ensure the weight of the packaged product with very high precision.

Ease of use, extremely rapid format change and wide customisation possibilities are the main characteristics of the FMT weight filler range.

Within the FMT range, the weight technology is declined in the linear version, for medium-low speeds, and in the rotary version, for higher speeds.

Different customisation options are available for this type of filler, depending on the type of product to be filled or the container to be processed.

The FMT weight fillers are available in two different versions

Vacuum filler

Questa tecnologia è ideale per colmare i contenitori in vetro, plastica o metallo con differenti tipi di liquido di governo per prodotti come verdura, frutta, tonno e carne.

I liquidi di governo impiegati solitamente sono aceto, olio, salamoia, salse e sciroppi.

L’operazione di colmatura avviene dopo aver aspirato l’aria esistente dentro al contenitore in cui è già presente il prodotto principale.

L’aria residua presente all’interno dello spazio di testa viene invece eliminata con un getto di vapore prima della chiusura del contenitore stesso (tramite capsulatrice o aggraffatrice).

La costruzione modulare ed estremamente personalizzabile delle colmatrici FMT le rende idonee ad essere utilizzate tanto nelle linee ad alta velocità quanto in quelle a medio- bassa capacità produttiva.

Per tutte le applicazioni in cui il dosaggio del liquido di governo sottovuoto non è richiesto, FMT è in grado di offrire ai propri clienti anche soluzioni con colmatrici lineari a pioggia.

In relazione alla tipologia di prodotto da riempire o al contenitore da lavorare, sono disponibili diverse opzioni, tra cui:

- Predisposizione CIP per lavaggio interno tramoggia ed esterno

- Gruppo di preparazione e riscaldamento dei liquidi di governo